Sawmill

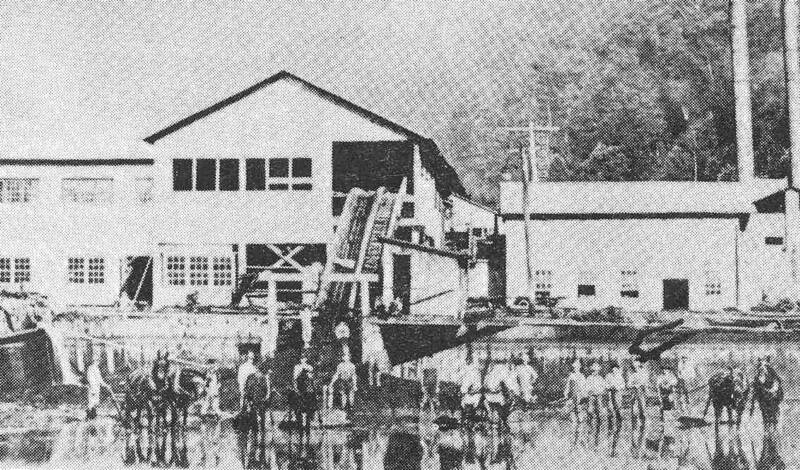

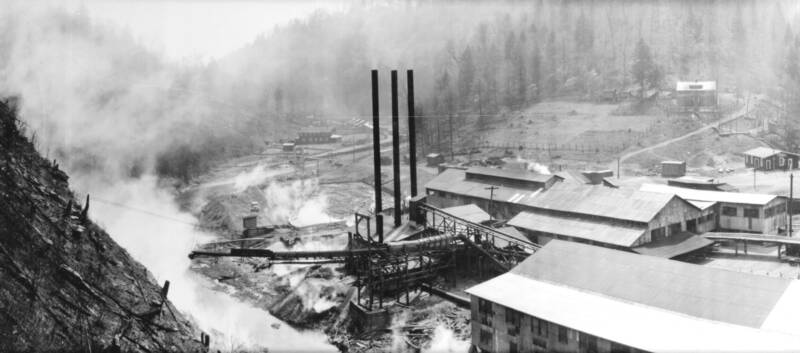

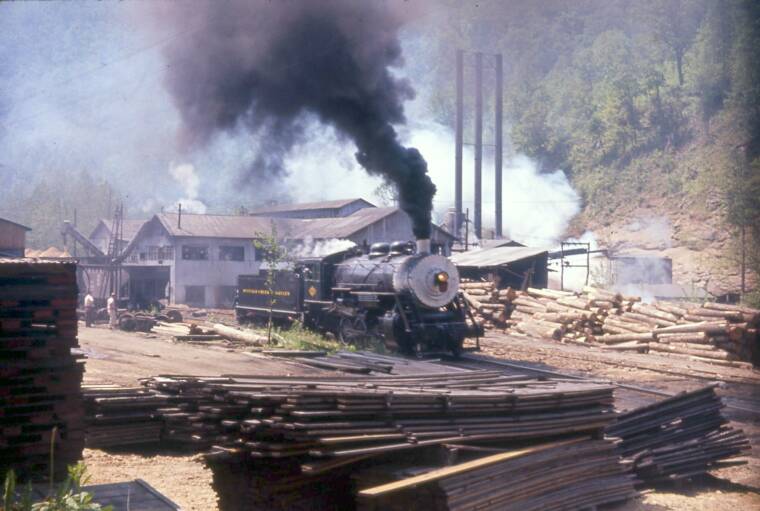

The bandsaw mill, apparently completed around 1918, and associated the buildings were sprawled across the scene at Swandale, although the company store and community center towered over it. This photo from page 53 of Warden's BC&G book shows the mill as it appeared probably in the 1920's. A notable feature here is the twin stacks from the power house. The earliest photo in Elvin's collection showing three stacks is dated April 30, 1930.

Both photos collection of Elvin Frame

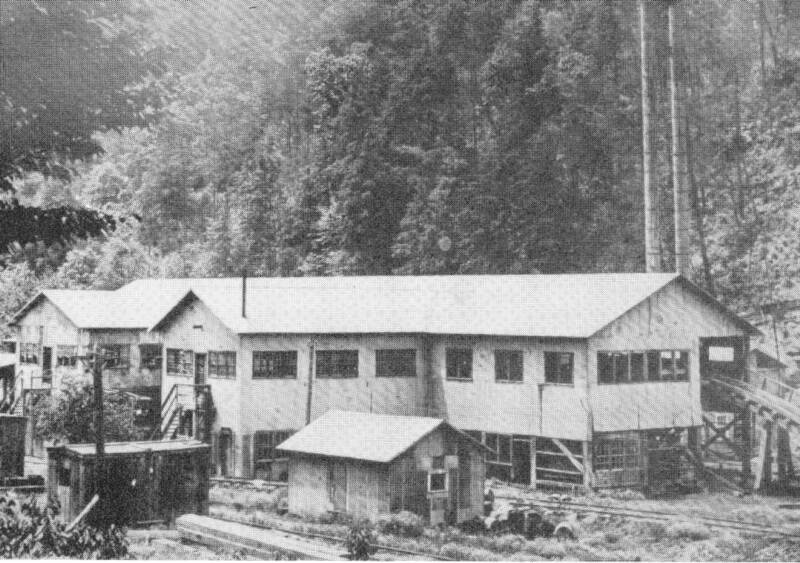

Collection of Jeff Butler

This photo from about the same time is the only one I've seen from this angle and it shows the powerhouse to the right, not visible in other photos.

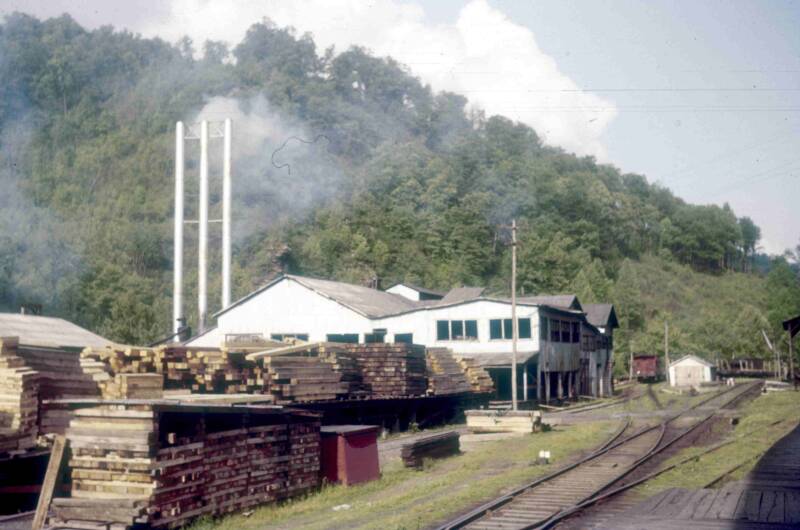

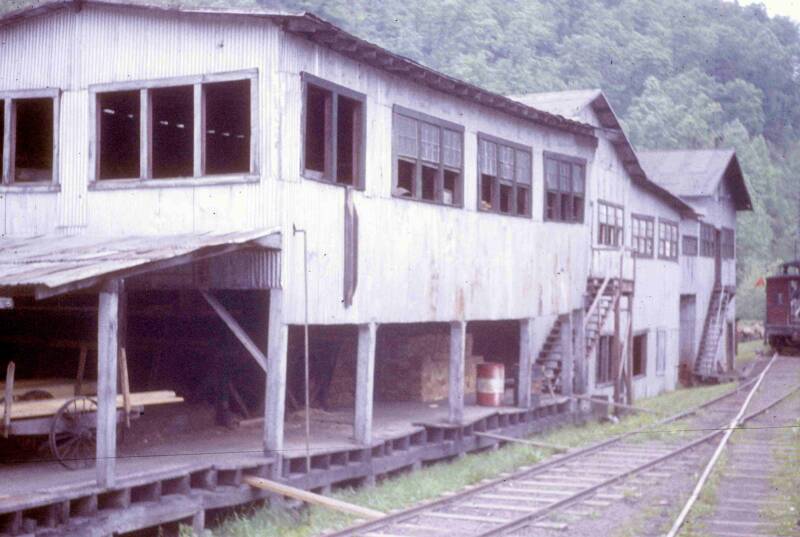

This photo shows almost the entire mill complex during the peak of operations probably in the 30's or 40's. Notice the rails on the platform for shuttling carts of lumber by hand to waiting cars or drying piles. The structure looks badly weathered in this view. This is the post-1930 "3 chimney" version of the mill.

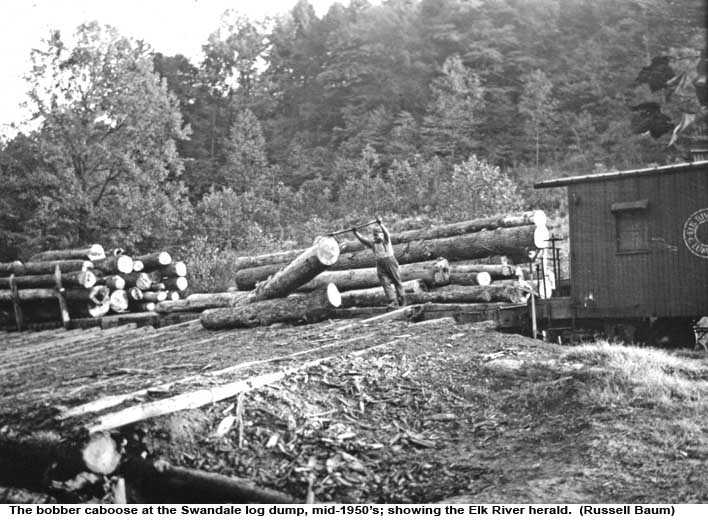

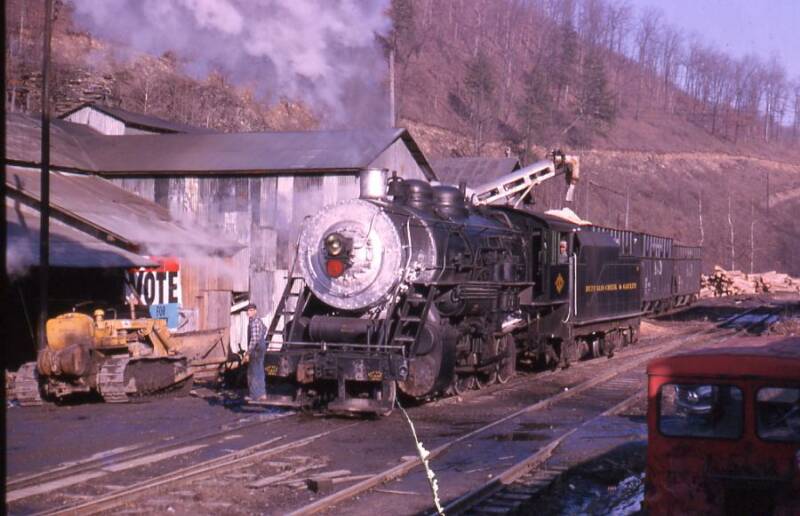

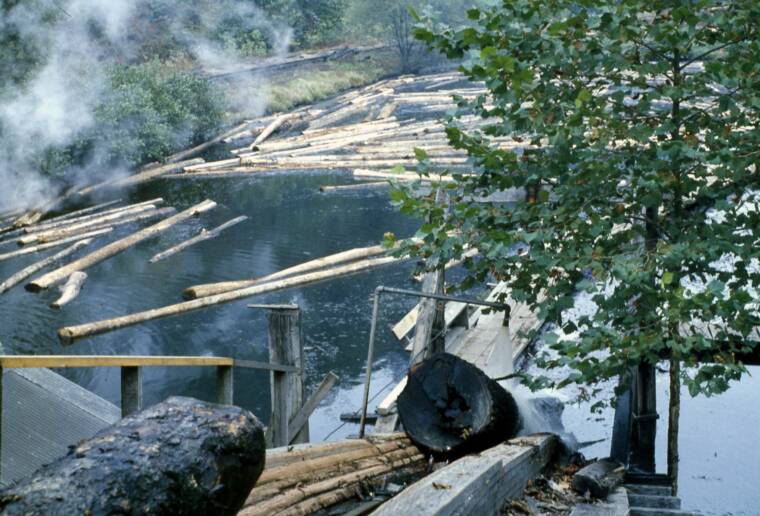

The procedure for unloading logs into the pond was typical backwoods...roll the logs down an incline and hope to not get hit by one! The logs were washed as they were pulled into the mill with a simple spray pipe. Also barely visible in the photo above are five tracks. The first heads around to the powerhouse (1). Coal was used to fire the powerhouse, as well as some sawdust, according to Bobby Caruthers. The second and third tracks (2) & (3) form the modest coaling facility for the ERC&L engines. The train is sitting on the fourth (4), the log dump track. The fifth track not really visible (5) is the BC&G main. The tracks (1) through (3) are quite visible by clicking on this photo to get to it's full size.

Russell Baum - Mid 1950's

Thanks to Dave Marquis for this great photo! The track arrangement is quite apparent here. Up the center is the BC&G main. On the right is the track to the ERC&L engine house. The caboose is sitting on the track that runs next to the log pond.

The building, including the smoke stacks, appear to be in pretty good repair although it is late in the game.

David Marquis photo - circa 1958

David Marquis photo - circa 1958

When GP took over, at least some of the wood chips or sawdust were hauled away in hoppers. The conveyor to load them is visible in the Sigman website photo above.

Switching chip hoppers makes an interesting operation on a model railroad.

1

2

3

4

5

Phil Ronfor - March 1957

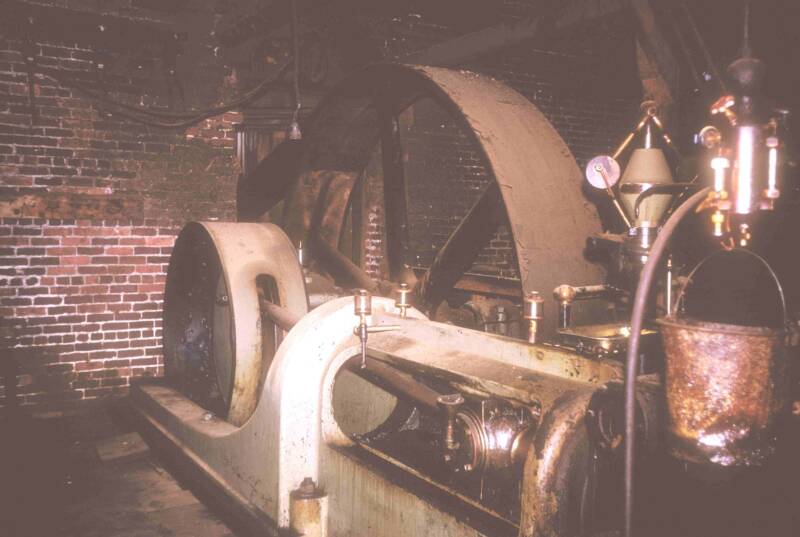

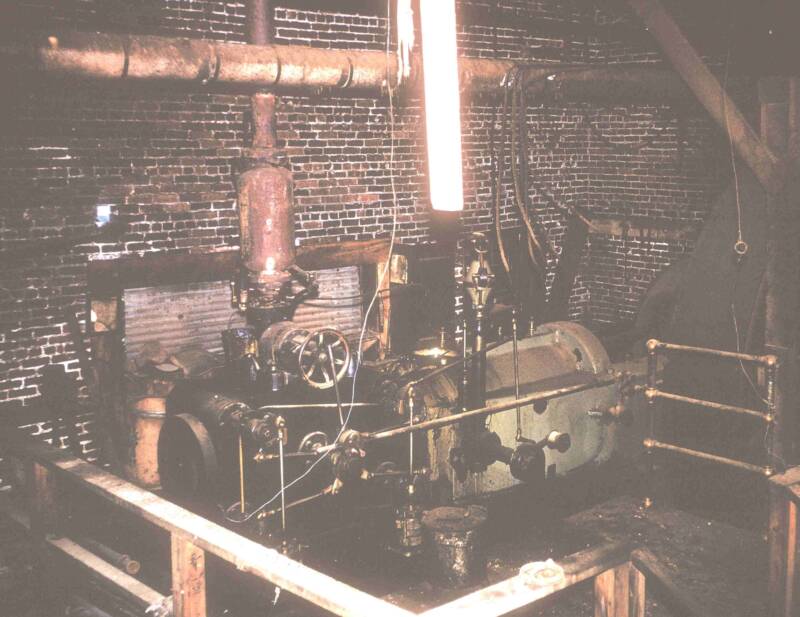

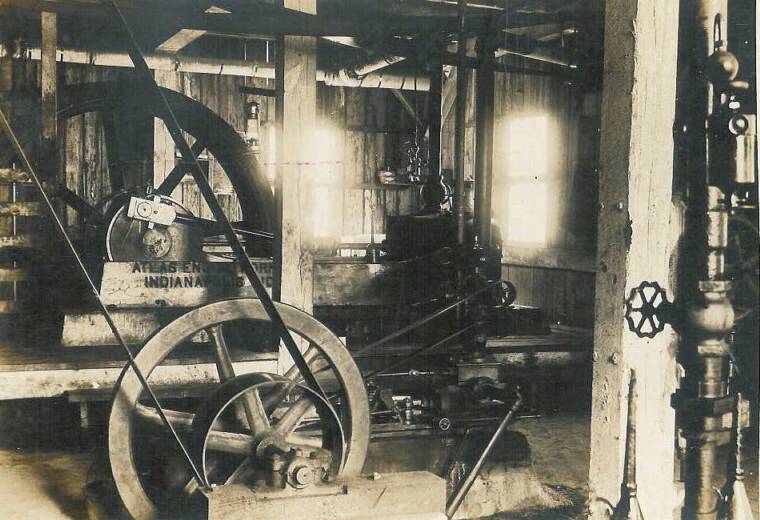

Dave Marquis did it again with these wonderful, and rare, photos of the steam engine and flywheel that powered the sawmill. The wall is one of the few brick structures that appears in any photos of the BC&G.

David Marquis photo - circa 1958

Collection of Elvin Frame

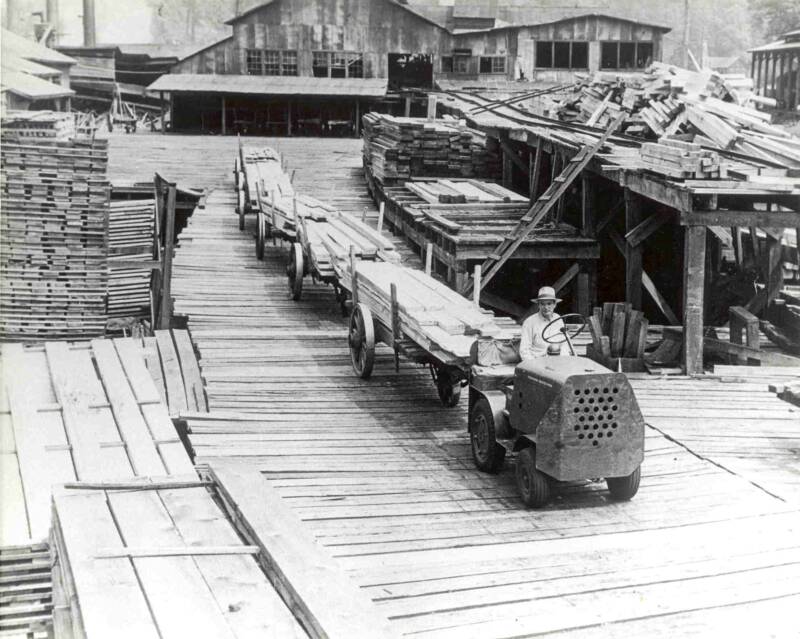

This facscinating photograph shows Freeman Nottingham driving the tractor with lumber carts in tow. Elvin believes this photo and the one above left were taken on the same day and it certainly seems like that could be the case based on the coloring of the mill. Just visible in the upper right corner is the open-sided engine house.

Log Pond

Here's another great early photograph from Elvin Frame's collection. While not dated, several observations can be made. First, these are earlier log cars than those used in the 1950's. These appear to be truss rod, I can't tell whether they are riding on arch-bar trucks, but I would guess they are. You can make out the letters "ERC" on the car nearest the camera. Also notice how small and simple the log dump ramp is compared to later photos. The walkway has a handrail in this photo that is gone in the photo below.

Cody Burdette says that the big building in the distance is the Boarding House in upper town. The little pitched roof shed with the window, he believes, is the old sand house. There was a swinging bridge to upper town just behind the sand house

The two photos below, one from Bobby Caruther's collection and one from Elvin Frame's collection show two views of the log pond when the log dump ramp is much, much larger. Elvin points out that the timbers making up the ramp itself are actually shaped square, like ties. This can be seen more clearly by enlarging the photo on the lower right.

Elvin Frame collection

Elvin Frame points out in his history of Swandale that "up until Georgia Pacific purchased Ritter after the sale of the ERC&L Co., sawdust and chips from the mill were conveyed to the furnace area and used for fuel. During the day the material was fed directly into the three furnaces by a chute from the overhead chain conveyor from the mill. Shaving from the lumber planner mill was conveyed to the furnaces in the same manner." The conveyor is marked (A) in the photo of the mill with the pile of ties at the top of this page. Elvin goes on "the larger slabs were conveyed by a chain out to the far side of the creek and dumped where they were burned. Between the mill and the creek a man pulled off slabs and threw them down a slanted wood chute behind the furnace area. These were then used during the night to fire the furnaces along with coal to keep the steam pressure up to a certain level in order to start the mill the next morning."

A

Sigman website photo

Cody Burdette points out that while the photo above right shows a conveyor for loading coal in the ERC&L engines, that conveyor didn't arrive until the last few years of operations. For years the engines were coaled by hand from a gondola of coal, as Cody recalls one of the BC&G steel gondolas.

While the Rich Run Mine at Widen closed in December of 1963, the Georgia-Pacific continued to operate the sawmill after that. The BC&G hauled lumber from Swandale to Dundon until February 27, 1965. According the Warden's book, "after that the Plymouth diesel took over the job of hauling finished lumber to Dundon. But G-P saw the supply of merchantable timber dwindling and the cost of logging what remained growing constantly. In 1968. the logging operation in Clay County was terminated. By this time, trucks were hauling the lumber to Dundon for loading on the flat cars at the B&O interchange."

The End of Operations

In September of 1963, just months before the Rich Run Mine closed, John Brown of Canada and some friends were railfanning the BC&G and caught this shot of #14 departing Swandale after her water stop. The now-dry log pond is clearly visible. The flat cars in front of the train are on the track that formerly ran adjacent to the log dump ramp. The sawdust loading conveyor is visible to the right in the photo.

John Brown photo September 1963

Bobby Caruthers collection from Doug Andre

Facts About the Log Pond

Cody Burdette has provided the following accounting about the forming of the log pond. He believes that the log pond was probably hand dug and it was fed from Barren She Creek by valves in the engine room of the sawmill. About once a year the pond was drained into the Buffalo Creek and a crew of men with shovels would shovel bark and mud out of it.

To keep the pond from freezing over in winter, the big mill engines exhaust was under the water in the pond, keeping to pond warm.

A short time after WM Ritter took over (1958), the pond was drained and they installed a debarker. As a result, there was no need to wash mud from the logs.

In the engine room were all the pumps, along with the dynamo that made electricity for the whole town of Swandale. The lights were in the town went out at midnight so that the boilers could cool down so the night fireman could clean the fires.

SAWMILL STEAM - by Cody Burdette

Steam heat from the mill was piped to the store, the Superintendent's house, the community building and the boarding houses. The dynamos also powered Swandale's streetlights. By the mid-50s, as people began buying refrigerators and TVs, the old dynamo could not furnish enough electricity so the Company allowed the electric company to bring power into Swandale.

The following material about the operation of the logpond was graciously provided by Mr. Nelson Spencer. Nelson was born in Swandale and lived there until 1943. While there are some differences in Nelson's recollections versus Cody's, there are more similarities.

"How was the pond formed? I can only guess. Back in those days they used horses and scoops if they had a lot of dirt and rock to move. They most likely had to use dynamite to break up rock. Once they had the pond dug out they put heavy timbers around the walls. They also had a gate that could be lifted to drain the pond. Why this? Over the years the dirt and bark from the logs would fill the pond and the water would not be deep enough to float the logs efficiently. On days they cut only soft wood they would kick the hardwoods out of the way and if there was a build up of dirt around the edges the pond would be smaller. So we clean the pond. Lift the gate, drain the pond and flush out the pond with fire hoses. How often was this done? I have no idea...possibly every 10, 15, or 20 years.

I saw them do this once. If one of the timbers around the pond had deteriorated and they had a leak that might be a good reason to shut it down or you might have a failure.

The water from Barren She did go into the pond. There was a sluice-way that ran from the Barren She into the lumber pond. I was acquainted with both ends. Barren She would go dry and no water would be going into the pond in dry months. They probably pulled water from Buffalo Creek or used the water from the well that was at the mill. The water into our houses came from that well. Some people said it came from Barren She but that is not so. It still was not safe to drink and that is why we had our own wells in town to get water for drinking and cooking.

Some people might say that they did not have the equipment to flush out the log pond with fire hoses, but they did. They had little fire houses where fire hoses were stored but I cannot remember where the hydrants were...maybe in these houses. If our little house down in the hollow or our bigger house on the hill had caught on fire they could have reached us with water. I do not know haw far the water lines ran down town or up town...possibly only to the community building. They wanted to be sure to protect the elite.

A modeler, Larry Smith, inquired about whether there was a 'slash burner' at the mill. Once again, Cody Burdette has provided the answer. According to Cody, "There was a long conveyor (labeled "A" in the photo above) that "dumped bark and any slabs that were not needed in the boiler room to a large open fire across the creek that burned 7 days a week, day and night. The hog in the mill made chips out of most of the slabs and the chips were sent to the boiler room on a different conveyor. Then a chute from the planing mill sent dry sawdust to the boiler room."

All the ERC&L facilities at Swandale deteriorated rapidly after abandonment. The three photos above and left, taken by Mike Ashley in 1973, indicate that the company store was already gone although the feed store still stood. The photo above shows some of the construction of the engine house. The two photos below by Bob Slavy were taken a in 1974.

Wood Chip Disposal

Cody provides this additional description: "The conveyor that carried the waste material to the burner went right by the boiler room. A man was stationed about half way out on this chain. He threw any slabs they wanted for the boiler room off of the chain and the excess slabs and material from the trimmer and edger in the mill went to the burner. The burner was just a big pile of waste, with no top, that burned day and night. It was across Buffalo Creek against a rock cliff. The conveyor chain was in a big wooden chute and us boys would play in this chute when the mill was not running. My first job at Swandale was cleaning the big mill after it would shut down in th evenings. I would get off the school bus and head for the mill. There was a large round tube from the planing mill to the boiler room that carried dry chips and sawdust to the boiler."

This is a portion of the panaoramic photo from the collection of Elvin Frame. It shows in great detail the rear of the mill and the conveyor system that Cody decribed and that he played on!

Elvin Frame has done a considerable amount of research on Swandale. According to documents he has, Pat Butler, the first land agent for the ERC&L Co. states "the first sawmill was built in 1910 and operated until late 1912. In 1913 a second circular mill was built down to tracks above the bridge. Then in early 1914 construction began on a bandsaw mill which due to the war wasn't completed until 1918.

The image to the right is a greatly enlarged portion of the panoramic photo available from the Clay County Historical Society and shows the second of the circular mills. Thanks to Phil Bonzon for extracting this image from the digital file,

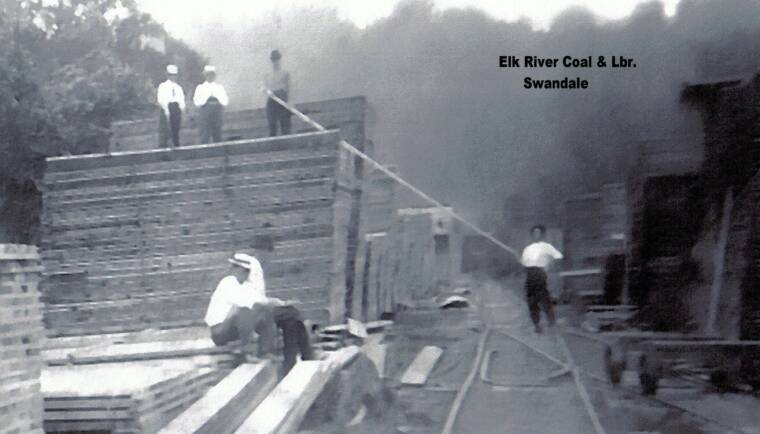

This undated, but apparently early, photo of workers stacking lumber at the mill gives some impression of the magnitude of the task of stacking all that wood! Also of note is the attire of the workers...white shirts and hats! I'm not sure I identify the exact location of this photo given that it appears wood is stacked on both sides, and very close to, the track.

Photo from the collection of Loretta Johnson Sample

This undated photo was received from Loretta Johnson Samples and at first glance appeared to be a duplicate of the image by Phil Ronfor above. But closer inspection reveals it to be a different photo taken from the same spot but at a different time. I've added it to the site because of the structures visible in the distance. (Click on the image to enlarge). The arch structure of the Swandale foot bridge is visible in the distance (A). Also visible is the boarding house (B) and residences can be seen in the distance (C).

A

C

B

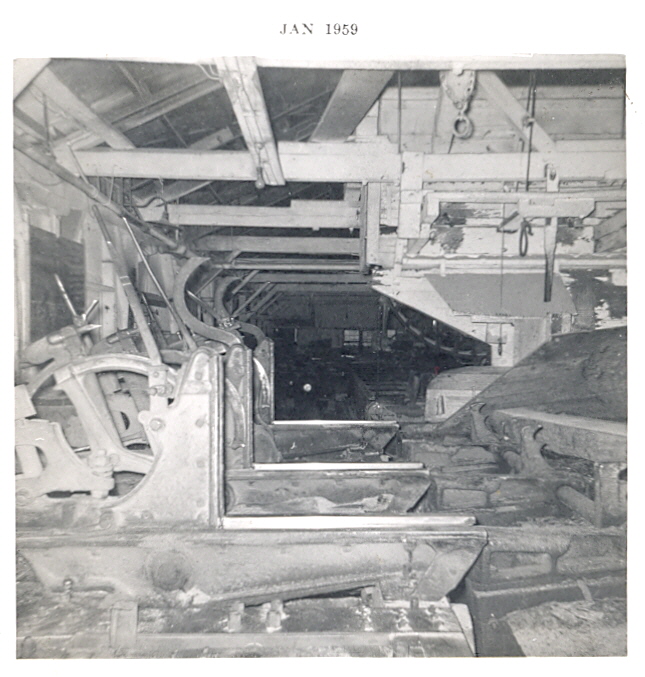

Saw Mill Interior Machinery

Elvin Frame has provided this rare photo of the interior of the section of the mill where the logs were cut into boards...a device called "the carriage'. The photo was taken in January 1959. Elvin states "a huge tapered round steel coil spring sat just behind the carriage which acted as a bumper in case the sawyer didn't stop th ecarriage on the return from another log or to saw another board.

Judy Gregorich Hart provides the following fascinating recollection about the log pond:

"When they drained the log pond my father would bring home LARGE turtles which he would kill and my mother would prepare for eating. She always told us the turtles had multiple taste and the most predominant one was chicken. She fried the meat just as one would fry chicken. I might add, I did not eat any. Killing the turtles seemed to be a struggle for my father. Of course, I was a small child and the scenario was probably not as bad as it seemed."

This photo shows what Cody Burdette believes to be the machine shop of the sawmill. It was located on the lower level of the mill. The undated photo is from the collection of John Beam. Do you suppose that is asbestos wrapped around the overhead pipe in the distance?

John Phillips photo - 10-2-1958

I've included this photo by John Phillips mostly because it is one of the few color photos of the log pond. Usually log ponds are muddy brown but in this photo is looks quite blue. I have always found it curious that a tree was allowed to grow right at the base of the jack slip. Notice that the mill is in operation...logs are coming up and the washer is on...and notice, too, the new board on the railing on the opposite side of the slip.

Cody Burdette points out that if you look at the hostler track (arrow) in the distance you can see the piles of ashes dropped from the engines. When the track got "filled up" with ash, crews used it to fill pot holes in the roads around Swandale.

"Hostler Track"

Cody Burdette recalls that Nobe Conner served as the assistant superintendent at Swandale for years up until the sale of the company in 1959.

John Phillips took this photo in May 1963, just a couple of months before operations at the Rich Run mine ended, but it's clear that the new owners had changed operations at the mill. By now the log pond had been drained as logs are piled in the area where the pond had been.