Current BC&G LAYOUT

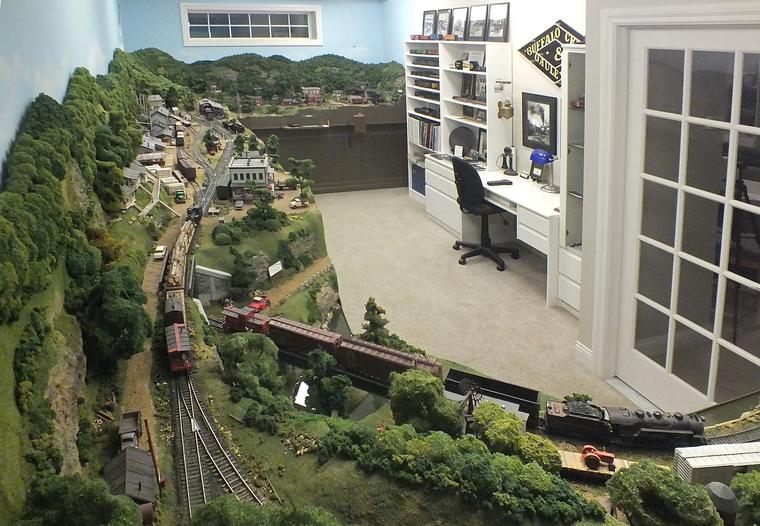

The new layout room measures 12' x 25'. I had the builder paint the walls sky blue and, after this photo was taken, install five 4-tube florescent light fixtures, carpet the floor, install ceiling speakers and put one of the wall outlets on a wall switch so that power to the layout can be turned off. As seen in the photo, there is a glass door to the layout room so it can be seen from the adjacent family room that doubles as a crew lounge.

THE MOVE and the NEW ROOM

The 'big' layout was disassembled over a period of several months. All the locomotives, rolling stock, structures, figures, motor vehicles, trees and scenic details were packed and carefully labeled. The lumber from the benchwork was cut to size for the new layout, marked and bundled as well. Lumber and track that wasn't going to be used on the new layout was donated to other S gaugers.

LAYOUT OBJECTIVES

Four primary and inter-related objectives drove the design of the new layout. All four were equally important and equally played into the decision making during the design process.

PROTOTYPE FIDELITY - After researching and modeling the BC&G and ERC&L logging activities for nearly 40 years I wanted to have the new layout be as representative of the prototype as it could be considering its size. I knew that significant compromises would be required but wanted to have the track plan and primary scenes based on the prototype. Equally important was to have an operating scheme in which all the trains run would be representative of trains that at one time or another ran on the real railroad.

PHOTOGRAPHIC OPPORTUNITIES - Sharing my prior layout with others through published photos was an enjoyable part of the hobby for me. I plan to do more of it with the new layout and so as I laid out the track plan and scenery, I was sensitive to where the good 'photo ops' would be. The bright lighting in the room was done, in part, to facilitate taking at least some photos without the need for auxiliary lighting.

OPERATING FUN - I hosted exactly 50 operating sessions on the prior layout and while the sessions will involve fewer crew members and last for shorter periods, I plan to 'operate' this new layout with friends. The track plan was developed simultaneously with the operating scheme. This ensured that the locations and sizes of sidings, staging, and run around tracks would accommodate the trains I plan to run. While trains will be shorter than on the large layout, and they will travel less distance between 'work sites', it should still be fun to operate.

OVERALL VISUAL IMPACT IN ROOM - The environment a layout is in can make or break it. I wanted the new layout to fit comfortably in the new space and for it to present a certain level of 'visual drama'. More layout could have been put in the room but I opted for plenty of 'white space' for viewers and operators. The layout shares the room with a desk, shelves and book cases so that my collection of memorabilia and reference material is close at hand.

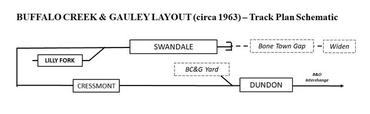

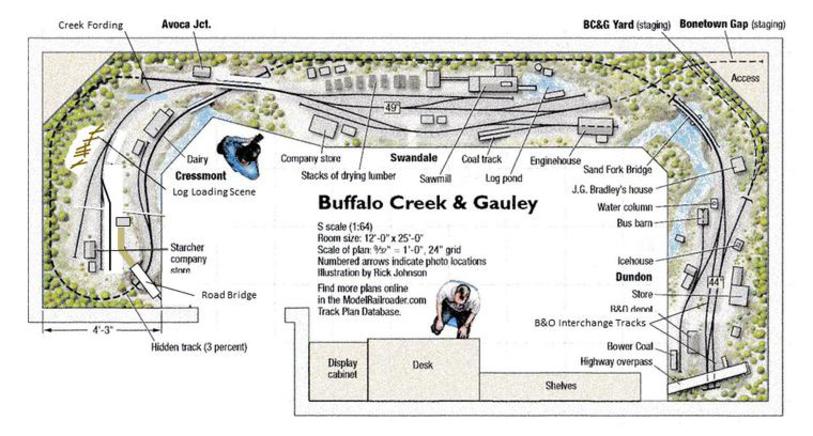

LAYOUT CONCEPT - BC&G in the FINAL YEARS

The track plan above, prepared by Kalmbach, illustrates the major elements of the plan. BC&G engines arrive at Dundon from BC&G Yard (staging) and pick up cars from the interchange. Leaving Dundon, the main line crosses the Sand Fork Bridge and then disappears. It emerges at Cressmont where there is short siding. The track disappears again, starts a 3% grade, and emerges near Avoca Junction (the junction with the log branch), crosses over itself and arrives at Swandale. The track continues past Swandale into hidden staging that represents the track to Bone Town Gap and the now unused track to Widen.

TRACK PLAN

BENCHWORK CONSTRUCTION

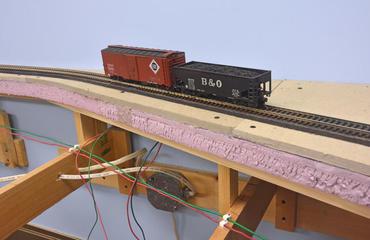

Construction has begun with the primary support structure being built with lumber from the big layout. The open grid is 1x2" 'select grade' lumber supported on risers. 1 1/2" foam is then bonded to the grid with Loctite PL300 Foamboard caulk adhesive. In the photo above right the brown-painted masonite is the base for the river feature and the foam is installed. In the photo to the left, a few of the structures have been set in place on what amounts to a full size mockup of the layout as the foam is just temporarily in place. Swandale is on the right, Cressmont is on the lower level and the log camp on the upper level in the distance.

OPERATING SCHEME

PROTOTYPE INSPIRATION

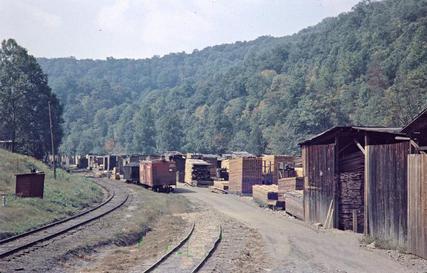

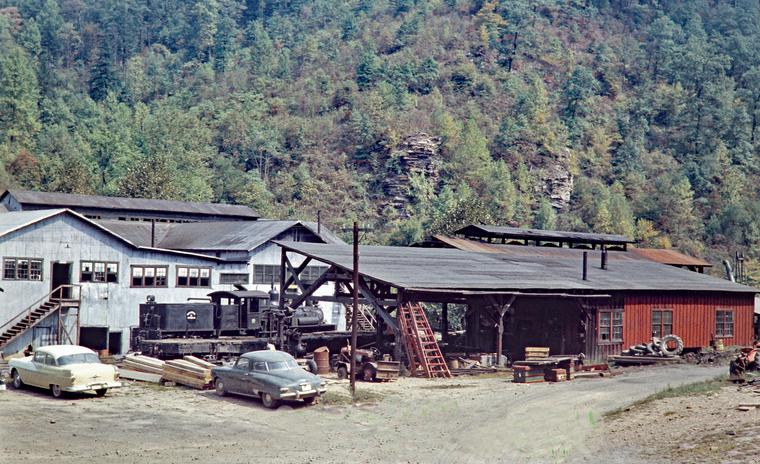

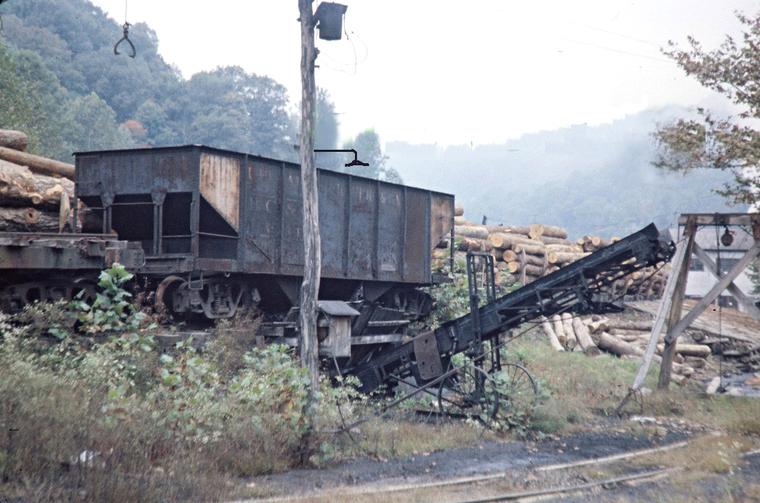

In planning the new layout I went back through all the photos on the site and selected a number which I used to inspire scenes not on the prior layout. Here are some of them. Others are posted on the website pages for each town on the layout.

I saw first hand during the speeder trip on the right- of-way that I took in 2007 that in many places the track ran on a narrow shelf between rock cuts and the creek. This look has been duplicated along the front edge of the layout.

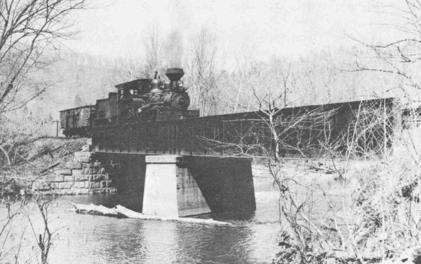

One of the most photographed places on the BC&G was the 142' Sand Fork Bridge. This photo shows how it looked after being rebuilt in the early 1960s with the large concrete center pylon. The full story on the bridge is HERE.

Swandale is the visual and operational center of the new layout. It will actually be a larger and more accurate representation than on the prior layout. A new, more accurate model of the engine house (left) has been built for the new layout and there is a specific siding serving a larger lumber stack (below). In addition, the coaling track for the logging engines has been included (below left) this time.

To the left is the benchwork at the Cressmont and Log Camp end of the layout. Notice that the DCC bus and wiring for the 9V structure lighting has been installed prior to the installation of the foam.

The bridge at Cressmont was also often photographed as it was easily accessible by road. An accurate representation of this bridge has been built for the layout. Notice this is a 'through' girder bridge while on the Sand Fork bridge the track runs on top of the girders.

Woodland Scenics foam riser system was used to create the 3% grade behind the log camp. It works just great for S track. It was glued to the 1 1/2" foam and the cork roadbed was bonded on top.

Two power outlets were installed on the front of the layout. They are connected to one of the wall outlets hidden behind the layout with appropriate Romex wire, electrical boxes, etc.)

This multiple-outlet box was connected to a wall outlet that is on a wall switch at the door to the layout room. All of the DCC and lighting systems will be connected to this group of outlets so that the entire layout can be powered on and off from the switch at the door. Notice that the Romex is held securely with either staples or by passing through holes in the benchwork. The red and green wires on the right are the buses for the 9V circuit for structure lighting. Small plastic 'clips' hold the wires in place on top of the rafters.

Cork roadbed from Scenery Unlimited was bonded to the foam with Loctite FoamBoard adhesive along centerlines drawn on the foam. The cork was then painted black with inexpensive flat black latex paint. The dotted line below the brush handle in the photo is the centerline for the siding behind the station that will be laid directly on the foam without roadbed.

At this point I temporarily laid some track and ran trains over 12' of track and discovered that there was a great deal of noise transmitted by the surface of the foam. After experimenting with foam and Homasote road bed, I concluded that the best way to quiet the noise was to cover the surface of the foam with 1/2" Homasote. I removed the cork roadbed already laid, installed the Homasote and reinstalled the cork.

Above Left - This is the Dundon area with the Homasote down and cork roadbed reinstalled.

Above - This is the portion of the roadbed that runs along the wall 'below' Swandale. The foam with Homasote overlay is clearly visible. The two pairs of wires coming from the track are feeders that will be attached to the DCC bus wires running horizontally above the rafters.

Left - The Homasote was bonded to the foam with Loctite Foamboard adhesive caulk. Drywall screws were used to hold the two together until the adhesive set. Cork roadbed was attached to the Homasote with the same caulk and held in place with pins until set.

After some experimentation, I developed a plaster-free technique for building landforms. Profiles are made from 1/2" pink foam. Black plastic screening (the type used for sun-blocking screens which has very small holes) is attached to the profiles with hot-melt glue. Bob Stelmach, a fellow S gauger, uses a thick texture paint called Homax (available at Home Depot) over metal screen. I used the same product, tinted green by Home Depot over the plastic screen material. When dried it produces a sturdy hardshell.

Click on town name to go to page with details on that section of the layout.

Many thanks to the folks at KALMBACH for allowing me to post this track plan that they prepared.

For the full story of how I decided to build this new layout, including how and why I decided to model the BC&G again in S scale, see MODEL RAILROAD PLANNING 2019. The article entitled "Same Railroad in a Smaller Space" begins on page 38.

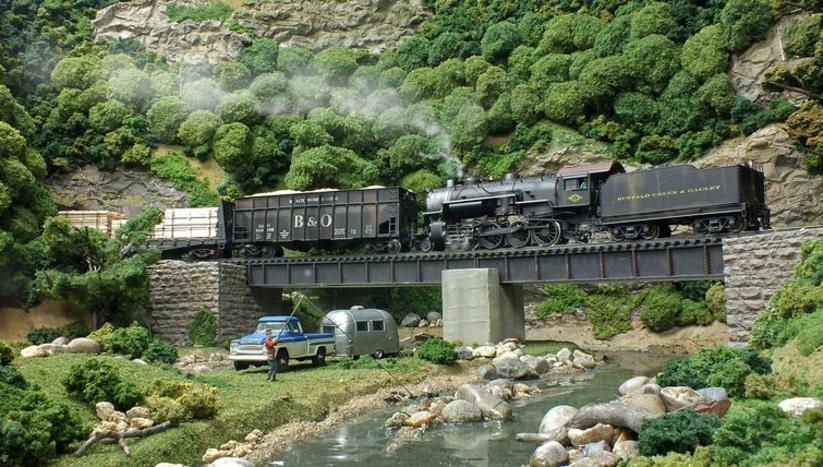

BC&G Consolidation #13 rolls across the Sand Fork Bridge with a loaded chip hopper and a flat car of lumber freshly cut at the Swandale mill. Shortly the train will arrive in Dundon and the crew will set the loads on the interchange track. It's the summer of 1964, the last summer of steam on the BC&G.

BC&G #13 on the Sand Fork Bridge

For a complete listing of all the published articles on my modeling CLICK HERE

The layout occupies three walls of the layout room and along the fourth wall is a desk and display shelves. The room is carpeted and illuminated by ceiling mounted fluorescent fixtures..

An article about the scenery techniques used on the new layout appears in the November 2020 issue of MODEL RAILROADER. BC&G #4 crossing the Sand Fork Bridge is featured on the cover.

New HARDSHELL CONSTRUCTION TECHNIQUE

BC&G #4 crossing the Sand Fork Bridge is featured on the cover of the November 2020 issue of MODEL RAILROADER. Inside is an article about scenery construction.

BC&G i#14 at Swandale is featured on the January 2021 issue of MODEL RAILROADER! Inside is an article about how to improve your layout photography.

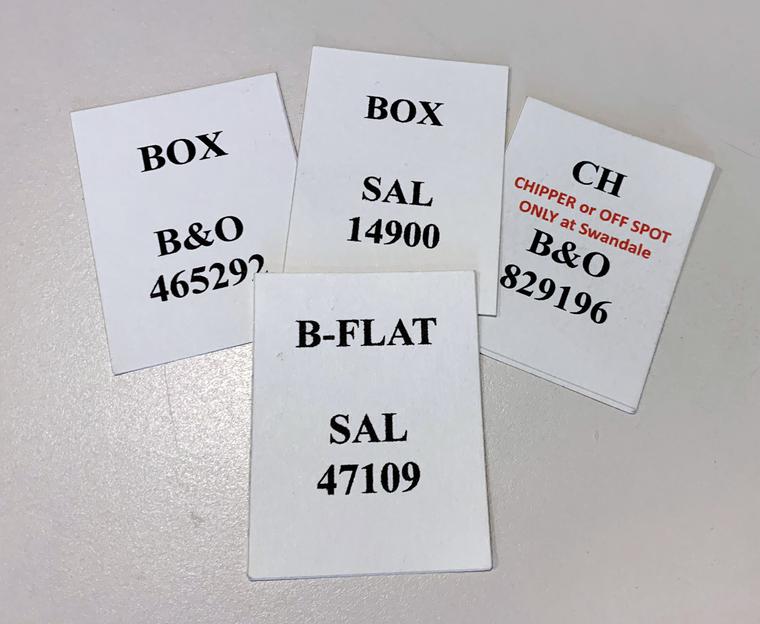

CAR ROUTING

Car routing is done using a simple card system. A card has been prepared for each car. Rather than being placed in a box specific to each spotting location as is typical with car card systems, all the cards for all the cars in each town are in a single box. To make up a train, the 'deck' is shuffled and a specified number of cards are drawn. Similarly for spotting, cards are drawn at random from those in the train for each spotting location. As the cards are drawn, a switch list is prepared. The cards are returned to the box and switching is done using the more prototypically correct switch list. This system generates unique switching patterns with each session. It's easy to swap cars onto and off of the layout as desired and simply swap the corresponding cards.

THE CARD-DRAW ROUTING SYSTEM IS EXPLAINED IN DETAIL IN A 6-Page ARTICLE IN

THE FEBRUARY 2025 ISSUE OF RAILROAD MODEL CRAFTSMAN

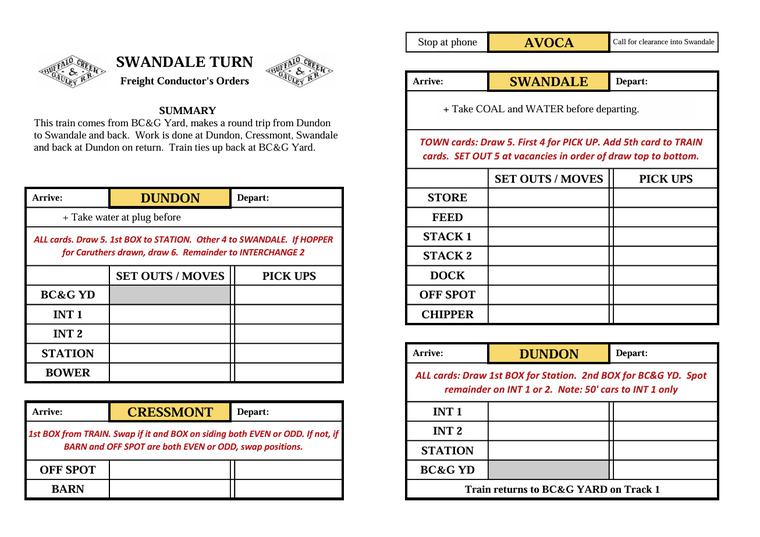

I developed the operating scheme for the new layout simultaneously with the development of the track plan although the scheme is continuously evolving. The location and capacities of run around tracks and sidings were established with specific train movements in mind. Car routing on the layout is accomplished using a card-draw system described below..

ERC&L Climax #3 is on the cover of the May/June 2021 NG GAZETTE. Inside there is a feature article on the new layout.

1964 - The Final Summer of Steam

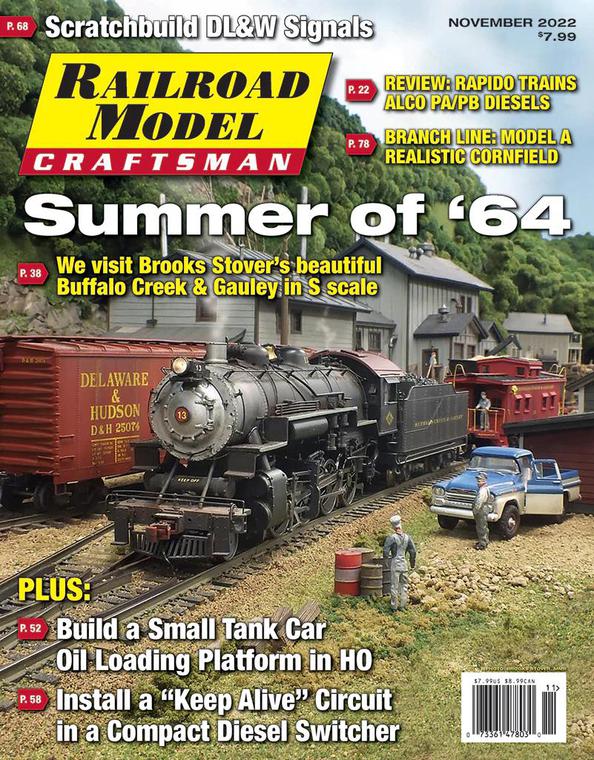

The cover story in the November 2022 Railroad Model Craftsman is the BC&G! There are 8 pages of new photos of the layout!

BC&G In

RAILROAD MODEL CRAFTSMAN

The BC&G is also featured in Kalmbach's

GREAT MODEL RAILROADS 2023!

Watch a series of 13 short videos covering all the major scenes and trains on the layout!

TRACK and CONTROLS

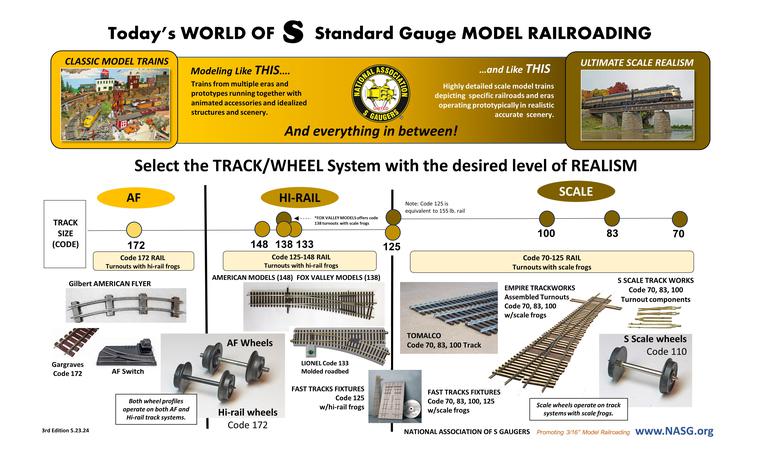

For full information on modeling in S, visit the website of the NATIONAL ASSOCIATION OF S GAUGERS (NASG) at www.NASG.org.

The layout is powered by North Coast Engineering's (NCE) excellent wireless DCC system. I use a ProCab primarily for programming and two Cab 06s for train operation.

All the track on the layout is by Fox Valley Models (FVM). The rail size is code 138 and the turnouts are their 'hi-rail' version with frogs to accommodate the hi-rail wheels on my equipment. Turnouts are manually thrown with Caboose ground throws.

The graphic to the right shows the three approaches to modeling in S and the rail size and wheel profiles associated with each. My layout is hi-rail by the NASG's nomenclature.

MODELER'S LICENSE

The layout represents the BC&G in its final years...1963-1965…with some liberties.

In December 1963, the Rich Run Mine at Widen was closed. After the closing, BC&G trains ran only 9 miles to Swandale where they delivered empty boxcars and flatcars for loading and picked up loaded cars of lumber destined for the B&O interchange at Dundon. Chip hoppers also appeared in the consists as wood chips from the sawmill were now being sold instead of burned. Trains ran just three days per week and were much shorter than in the golden years with 4-6 cars being typical. Because there was no place to turn locomotives at Swandale, BC&G engines ran tender-first back to Dundon.

Logging trains were handled by the 45-ton Plymouth #20. Climax #3 had gone out of service in 1960. Shay #19 and Mack Motor A were still on the property but not in regular service.

Some liberties were taken on the layout. The Dundon and Swandale company stores and the Cressmont dairy were all closed in 1958 when the ERC&L Co. was dissolved after the sale of the coal operation to Pittston Coal and the logging operation to Wm. Ritter in 1958. These all remain open on the layout. The log pond at the Swandale mill had been filled in by the late 1950s but it remains as a pond on the layout. The Starcher company store out on the Lilly Fork was long gone by the 1960s. It’s still in operation on the layout.

As there is no appropriate Shay available in S, a 3-truck Climax #19 represents Shay #19 on the layout. The Mack Motor A is still in service.

The Warden books says that the track to Widen remained open even after the mine closed. The track was used to assist dismantling the mine and perhaps supplying Widen. BC&G Consolidations normally handle these trains but occasionally BC&G Whitcomb #20 is used to power the work train.

On the layout the B&O trains are powered by a variety of engines including B&O GP35s and GP9s and occasionally WM GP9 6414 and B&O RS-1 9185, engines that were leased by Majestic Mining in the 1970s.

See "OPERATING SCHEME' section below for a complete description of the trains that are run on the layout.

TRAINS ORIGINATING IN DUNDON

1. BC&G Milk Train 1 – Mack Railbus ‘A’ moves out of barn, stops for gas at pump, picks up ice at ice house then passengers board at Dundon station. The bus departs Dundon, then makes a stop at the Cressmont dairy and proceeds to Swandale and ties up at the Boarding House. (Runs as Extra with no printed orders.)

2. BC&G Swandale Turn - BC&G Consolidation arrives at Dundon from BC&G Yard (hidden staging) with caboose C-1, a boxcar and a caboose. It switches station track and then makes up a train of 3 or 4 cars from the B&O Interchange Tracks and departs for Cressmont. After switching Cressmont it continues to Swandale where it switches the mill, lumber docks and store, then makes up return train of finished lumber and chip hoppers. The train returns to Dundon, switches the station and then spots loads on Interchange Tracks before returning to BC&G Yard.

3. BC&G Swandale Mixed – Operates similar to Swandale Turn (above) but with a coach instead of caboose C-1. The consist is limited to 3 cars plus the coach.

4. B&O Grafton Local - B&O GP-35 3768 or B&O GP9 6472 (or WM GP9 6414 or B&O RS-1 9185) with five freight cars and B&O caboose backs into Dundon from Grafton (hidden staging Track 2) and switches interchange tracks 1 and 2, swapping as many cars as desired, then returns to Grafton (hidden staging Track 2). (Runs as Extra with no printed orders. Cars are swapped as desired.)

TRAINS ORIGINATING IN SWANDALE

5. ERC&L Log Train ("Lilly Special") – After service, Climax #19 makes up train of 2 empty log flats from the log pond track, and a MOW car, and the logging caboose. The train departs for the log camp at Starcher, swaps loads for empties, exchanges the MOW car, and spots the flat car-mounted crane in position for loading empties. After switching is complete, the train returns to Swandale, spots loaded log flats at the log pond and the MOW car. The engine returns to the Engine House.

6. ERC&L Swandale Switcher – Climax #19 switches Swandale rearranges as many cars as desired, getting them into position for loading and pickup. (No printed orders.)

7. BC&G Milk Train 2 – Bus A departs Swandale, makes stop at Cressmont and proceeds to Dundon station to unload passenger then returns to bus barn. (Runs as Extra with no printed orders.)

8. Widen Work Extra – A BC&G Consolidation (alternately Whitcomb #20 or B&O Baldwin) arrives from Widen/Bone Town Gap with a work train of a home road MOW car, an interchange MOW car, a boxcar and Dining Car X-6. It switches at Swandale, Cressmont, Dundon both directions, returning to WIden.

9. ERC&L Dundon Turn – This train emulates the use of the Plymouth diesel to haul finished lumber to Dundon as was done after the end of steam in Feb. 1965. The Plymouth picks up two or three cars of finished lumber and the bobber caboose and makes its way to Dundon where the cars are set out on the Interchange Tracks. It returns to Swandale with two or three cars for loading, occasionally making a stop at Cressmont. (This train ran only after the end of steam in 1965.)

TRAINS ORIGINATING IN STARCHER

10. ERC&L Log Train "Cannon Ball Special" - Plymouth #20 makes up train of 2 loaded log flats and a MOW car at Starcher, proceeds to Swandale, swaps the loads for empties on the pond track, swaps the MOW car and then returns to Starcher and sets out the empty flats.

11. Cressmont Turn - Plymouth #20 picks up an MOW car and caboose at Starcher, goes to Swandale to swap MOW car, then to Cressmont to swap MOW car and then back to Starcher. (This train runs as Extra without orders. Cars are swapped as desired.)

These 11 trains provide a variety of operating experiences starting from both ends of the railroad using a variety of motive power. The operations for these trains vary in length from about 15 minutes to as long as 45 minutes.